Compressive Stress Formula in Concrete and Building Materials

Ever wonder how skyscrapers stand tall against the relentless pull of gravity? Or how bridges withstand the constant pounding of traffic? The secret lies, in part, in understanding compressive stress. It's a fundamental concept in civil and mechanical engineering, particularly when dealing with materials like concrete, steel, and wood – the very backbone of our built environment. Mastering the compressive stress formula allows engineers to design structures that are safe, durable, and capable of withstanding enormous loads.

Understanding Compressive Stress

Compressive stress is the stress state caused by a force that pushes or compresses a material. Imagine squeezing a rubber ball; the stress you're applying is compressive. This type of stress is crucial in the design of columns, foundations, and other structural elements designed to resist crushing.

Think of it like this: tensile stress is like pulling on a rope, while compressive stress is like pushing on a brick. Both are stresses, but they act in opposite directions. Understanding the difference is essential for proper structural design and failure analysis.

Defining Compressive Stress

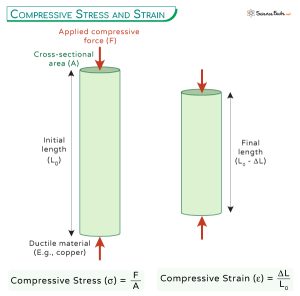

Compressive stress (σc) is defined as the force (F) applied perpendicular to a surface divided by the area (A) over which the force is distributed. The formula is expressed as: σc = F/A

Where:

- σc is the compressive stress, typically measured in Pascals (Pa) or pounds per square inch (psi).

- F is the compressive force applied, measured in Newtons (N) or pounds (lbs).

- A is the cross-sectional area of the material being compressed, measured in square meters (m2) or square inches (in2).

Units of Measurement

Using the correct units is vital for accurate calculations. In the SI system, we use Pascals (Pa) for stress, Newtons (N) for force, and square meters (m2) for area. In the imperial system, we often use pounds per square inch (psi) for stress, pounds (lbs) for force, and square inches (in2) for area.

Calculating Compressive Stress: A Step-by-Step Guide

Calculating compressive stress is straightforward, but precision is key. Here’s a step-by-step guide to ensure accuracy in your calculations.

Step 1: Identify the Compressive Force (F): Determine the magnitude of the force acting on the material. Make sure it is perpendicular to the surface.

Step 2: Determine the Cross-Sectional Area (A): Calculate the area over which the force is applied. For a column, this would be the area of its cross-section (e.g., length x width for a rectangular column, πr2 for a circular column).

Step 3: Apply the Compressive Stress Formula (σc = F/A): Divide the force by the area to find the compressive stress. Ensure that your units are consistent.

Example Calculation

Let's say a concrete column with a cross-sectional area of 0.25 m2 is subjected to a compressive force of 500,000 N. To find the compressive stress, we use the formula:

σc = F/A = 500,000 N / 0.25 m2 = 2,000,000 Pa or 2 MPa.

This means the compressive stress on the column is 2 Megapascals.

Factors Affecting Compressive Strength

While the compressive stress formula provides a way to calculate the stress on a material, several factors influence the material's ability to withstand that stress, which is known as its compressive strength.

Material Properties: Different materials have different compressive strengths. Concrete, for example, has a much higher compressive strength than wood.

Mix Design (for Concrete): The water-cement ratio, aggregate type, and admixtures used in concrete significantly affect its compressive strength.

Curing Conditions: Proper curing is crucial for concrete to achieve its designed compressive strength. Temperature and humidity during curing can greatly impact the final strength.

Loading Rate: The speed at which the force is applied can also influence the material’s response. Rapid loading might lead to different results than slow, sustained loading.

Practical Applications of Compressive Stress

Understanding compressive stress isn't just theoretical; it has countless practical applications in civil engineering, architecture, and material science.

Column Design: Ensuring that columns can withstand the compressive loads from the structure above is paramount. Engineers use the compressive stress formula to determine the required dimensions and material properties of columns.

Foundation Design: Foundations must be able to bear the weight of the entire structure. Understanding compressive stress helps engineers design foundations that can safely distribute the load to the ground.

Material Selection: When choosing materials for a project, engineers consider their compressive strength. Concrete is often used in structures subjected to high compressive loads due to its excellent compressive strength.

Compressive vs. Tensile Stress: Key Differences

While both are types of stress, compressive and tensile stress are fundamentally different and critical to understand for accurate structural design.

Direction of Force: Compressive stress results from forces pushing inwards on a material, while tensile stress results from forces pulling outwards.

Material Behavior: Materials often behave differently under compressive and tensile stress. For example, concrete is strong in compression but weak in tension.

Failure Modes: Compressive stress can lead to buckling or crushing, while tensile stress can lead to cracking or breaking.

Advantages and Disadvantages of High Compressive Strength Materials

Using materials with high compressive strength offers several advantages, but also some potential drawbacks.

Advantages:

- Increased load-bearing capacity.

- Improved structural stability.

- Longer lifespan for structures.

Disadvantages:

- Can be brittle and prone to sudden failure.

- May be more expensive than lower-strength materials.

- May require specialized construction techniques.

Common Mistakes to Avoid

When working with the compressive stress formula, avoid these common errors to ensure accurate and reliable results.

Incorrect Units: Always ensure that all units are consistent (e.g., all SI units or all imperial units).

Incorrect Area Calculation: Double-check the calculation of the cross-sectional area. An incorrect area will lead to a significant error in the stress calculation.

Ignoring Other Stresses: Remember that compressive stress is often present alongside other stresses, such as tensile or shear stress. Consider all stresses in your design.

Frequently Asked Questions

What is the difference between compressive stress and compressive strength?

Compressive stress is the force per unit area acting on a material, while compressive strength is the maximum compressive stress a material can withstand before failure.

Why is concrete strong in compression but weak in tension?

Concrete's granular structure and the way cement binds the aggregate make it resistant to being pushed together (compression). However, it lacks the internal structure to resist being pulled apart (tension), leading to cracking.

How does temperature affect the compressive strength of concrete?

High temperatures during curing can cause rapid hydration, leading to weaker concrete. Conversely, freezing temperatures can cause water within the concrete to expand, leading to cracking and reduced strength.

What are some common examples of structures designed to withstand compressive stress?

Examples include columns in buildings, bridge piers, dams, and retaining walls. All these structures are designed to bear significant compressive loads.

Can the compressive stress formula be used for all materials?

Yes, the formula σc = F/A can be used for any material subjected to a compressive force, but it's crucial to understand the material's properties and behavior under compression for accurate design.

How do engineers ensure that a structure can withstand the designed compressive stress?

Engineers use safety factors in their calculations, select appropriate materials with known compressive strengths, and perform rigorous testing to ensure the structure can safely withstand the anticipated loads.

Conclusion

Understanding the compressive stress formula is crucial for anyone involved in structural design, construction, or material science. It enables us to predict how materials will behave under pressure, allowing us to build safer, more durable, and more efficient structures. By mastering the fundamentals and avoiding common pitfalls, you can confidently apply this knowledge to real-world engineering challenges. So, keep pushing forward, keep learning, and keep building a better future, one calculation at a time!

Posting Komentar untuk "Compressive Stress Formula in Concrete and Building Materials"