Maximum Stress Formula vs Working Stress Formula

Ever wonder how bridges stand strong against tons of traffic, or how airplanes manage to fly without their wings snapping off? The answer lies in the careful calculations engineers make using concepts like maximum stress and working stress. These aren't just abstract ideas; they are essential for ensuring the safety and reliability of everything around us, from buildings to vehicles. Understanding these formulas is vital for anyone involved in mechanical engineering, structural design, or any field where material strength is critical.

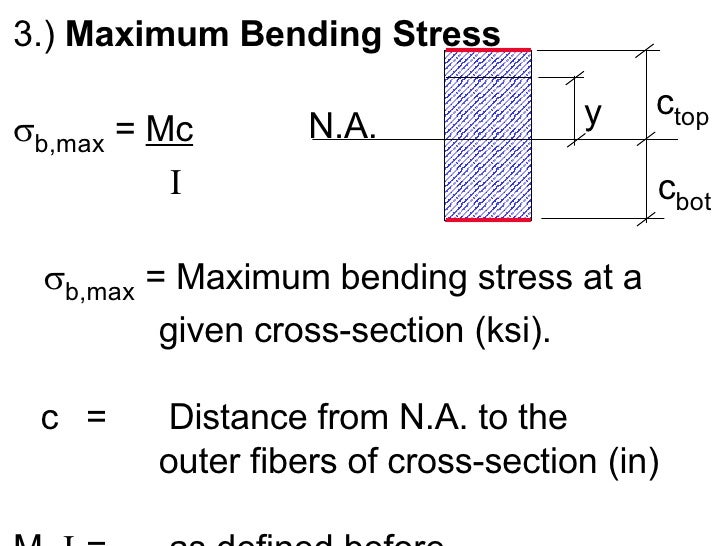

Understanding Maximum Stress

Maximum stress, often referred to as ultimate tensile stress (UTS) or ultimate compressive stress, represents the highest amount of stress a material can withstand before it begins to permanently deform or fracture. This is a crucial material property obtained through tensile testing, where a sample of the material is subjected to increasing tensile force until it breaks. The maximum stress formula essentially helps us identify this breaking point.

Formula and Calculation

The formula for maximum stress (σmax) is quite straightforward:

σmax = Fmax / A

Where:

- σmax is the maximum stress

- Fmax is the maximum force applied

- A is the original cross-sectional area of the material

Let's say you're testing a steel bar with a cross-sectional area of 0.001 m2. During the test, the bar breaks when subjected to a force of 50,000 N. The maximum stress would then be:

σmax = 50,000 N / 0.001 m2 = 50,000,000 N/m2 or 50 MPa

Practical Applications of Maximum Stress

Knowing the maximum stress is fundamental in failure analysis. It helps engineers determine if a material is being subjected to excessive loads that could lead to catastrophic failure. This information is essential in material selection and design optimization, allowing engineers to choose the right materials and dimensions for a given application. For example, in designing a car chassis, engineers use the maximum stress values of different steel alloys to ensure the chassis can withstand impact during a collision.

Limitations of Using Maximum Stress Alone

While maximum stress provides a crucial benchmark, it doesn’t tell the whole story. Using it alone can be risky, as it doesn't account for factors like material defects, fatigue, or corrosion, which can significantly reduce a material's ability to withstand stress over time. This is where the working stress formula comes in.

Exploring Working Stress

Working stress, also known as allowable stress or design stress, is a more conservative measure of stress that engineers use in practical designs. It's the maximum stress that a material is allowed to experience under normal operating conditions. The working stress is always lower than the maximum stress to provide a safety margin, accounting for uncertainties and potential risks.

Formula and Calculation

The working stress (σw) is calculated by dividing the maximum stress (σmax) by a factor of safety (FS):

σw = σmax / FS

The factor of safety is a dimensionless number greater than 1, chosen based on the application's criticality, material properties, and potential risks. A higher factor of safety indicates a more conservative design.

Let's continue with the previous example of the steel bar with a maximum stress of 50 MPa. If we decide to use a factor of safety of 3, the working stress would be:

σw = 50 MPa / 3 ≈ 16.67 MPa

This means that in the actual design, the steel bar should never be subjected to stress exceeding 16.67 MPa to ensure safe operation.

Choosing the Right Factor of Safety

Selecting an appropriate factor of safety is critical. It depends on several factors, including:

- The accuracy of the load calculations

- The material's properties and variability

- The consequences of failure (e.g., loss of life, environmental damage, economic losses)

- The operating environment (temperature, humidity, corrosion)

- The level of quality control during manufacturing and construction

For critical applications like aircraft components, a high factor of safety (e.g., 3 or higher) is typically used. For less critical applications, a lower factor of safety may be acceptable.

Advantages of Using Working Stress

Using working stress provides a safety cushion, accounting for uncertainties in material properties, manufacturing processes, and operating conditions. It helps prevent premature failure and ensures the long-term reliability of structures and machines. It also simplifies the design process by providing a clear allowable stress limit.

Disadvantages of Using Working Stress

The main disadvantage is that it can lead to over-designed structures, which are heavier and more expensive than necessary. This is because the factor of safety introduces a degree of conservatism. In some cases, more sophisticated design methods, such as probabilistic design, may be used to optimize the design while maintaining an acceptable level of safety.

Maximum Stress vs. Working Stress: A Comparison

The key difference between maximum stress and working stress lies in their purpose. Maximum stress represents the material's ultimate strength, while working stress represents the allowable stress in a real-world application. Maximum stress is a material property, while working stress is a design parameter. Maximum stress is used to determine the limits of a material, while working stress is used to ensure the safety and reliability of a design.

Think of it this way: Maximum stress is like knowing the maximum weight a person can lift, while working stress is like knowing how much weight they should lift regularly to avoid injury.

Case Study: Bridge Design

Imagine designing a bridge to withstand the weight of vehicles. Engineers first determine the maximum stress that the bridge's steel beams can handle before failing. They then apply a factor of safety (typically 2 or higher) to calculate the working stress. The bridge's design ensures that the stress experienced by the beams under normal traffic conditions never exceeds the calculated working stress, providing a safety margin and ensuring the bridge's longevity.

Practical Implications for Students and Professionals

For students studying mechanical engineering or related fields, understanding the concepts of maximum stress and working stress is crucial for learning how to design safe and reliable structures and machines. Professionals in these fields use these concepts daily to analyze designs, select materials, and prevent failures. A solid grasp of these principles allows for more efficient and safe designs, avoiding costly mistakes and ensuring public safety.

Frequently Asked Questions

What happens if the working stress is exceeded?

If the working stress is exceeded, the structure or component is at risk of failure. This could lead to permanent deformation, cracking, or complete collapse, depending on the material, the magnitude of the excess stress, and the duration of the overload.

How does temperature affect maximum stress?

Temperature can significantly affect the maximum stress of a material. Generally, as temperature increases, the maximum stress decreases. This is because higher temperatures can weaken the material's internal bonds.

Is the factor of safety always a fixed value?

No, the factor of safety is not always a fixed value. It varies depending on the application, the material, and the level of uncertainty involved. Engineering codes and standards often provide guidelines for selecting appropriate factors of safety for different situations.

What are some common causes of stress concentrations?

Stress concentrations occur at points where the geometry of a structure changes abruptly, such as corners, holes, and notches. These areas experience higher stress levels than the surrounding material, increasing the risk of failure.

How do I determine the appropriate factor of safety for a specific design?

Determining the appropriate factor of safety involves considering several factors, including the material properties, the accuracy of the load calculations, the consequences of failure, and the operating environment. Consulting relevant engineering codes and standards is essential.

Can I use finite element analysis (FEA) to determine maximum stress?

Yes, finite element analysis (FEA) is a powerful tool for determining stress distributions in complex structures. FEA software can accurately predict the maximum stress levels and identify areas of stress concentration, helping engineers optimize their designs.

Conclusion

Mastering the concepts of maximum stress and working stress is vital for ensuring the safety and reliability of engineered systems. By understanding these principles and applying them correctly, engineers can design structures and machines that are both efficient and safe. Don't just aim to build; aim to build strong and smart. Keep exploring, keep learning, and always prioritize safety in your designs!

Posting Komentar untuk "Maximum Stress Formula vs Working Stress Formula"