Maximum Stress Formula in Strength of Materials

Ever wonder why a bridge can withstand tons of traffic, or how an airplane wing manages to stay intact during flight? The secret lies in understanding the principles of strength of materials, and at the heart of it all is the concept of maximum stress. Knowing how to calculate this crucial value is essential for engineers and anyone involved in structural design because it helps predict when a material will yield or fracture under load.

Understanding Stress in Materials

In mechanical engineering, stress refers to the internal forces that molecules within a continuous material exert on each other, while strain is the deformation of the material caused by this stress. Understanding both is crucial for any structural design to prevent failures.

Think of it like this: Imagine you're pulling on a rubber band. The force you apply creates stress within the rubber, and the amount the rubber stretches is the strain. The maximum stress, then, is the highest amount of internal force the material can withstand before it starts to permanently deform or break.

Tensile and Compressive Stress

Stress can be either tensile (pulling or stretching) or compressive (pushing or squeezing). Tensile stress tends to elongate materials, while compressive stress shortens them. Many real-world structures experience both types simultaneously. Determining the maximum of either is crucial for safe designs.

Shear Stress

Shear stress occurs when forces act parallel to a surface, causing one part of the material to slide relative to another. Think of cutting paper with scissors; the blades apply shear stress to the paper fibers.

The Maximum Stress Formula: A Deep Dive

The specific formula for maximum stress depends on the type of loading and the geometry of the object. However, the fundamental principle remains the same: we need to relate the applied force to the cross-sectional area over which it acts.

For a simple tensile or compressive load, the formula is:

σ = F/A

Where:

- σ (sigma) represents stress (usually in Pascals (Pa) or pounds per square inch (psi)).

- F is the applied force (in Newtons (N) or pounds (lb)).

- A is the cross-sectional area (in square meters (m²) or square inches (in²)) perpendicular to the force.

Example Calculation

Let's say a steel rod with a cross-sectional area of 0.001 m² is subjected to a tensile force of 50,000 N. The stress on the rod would be:

σ = 50,000 N / 0.001 m² = 50,000,000 Pa or 50 MPa.

This calculated stress must be compared to the steel's yield strength (the point at which it starts to deform permanently) and ultimate tensile strength (the point at which it fractures) to ensure the rod's safety.

Beyond Simple Loads: Bending and Torsion

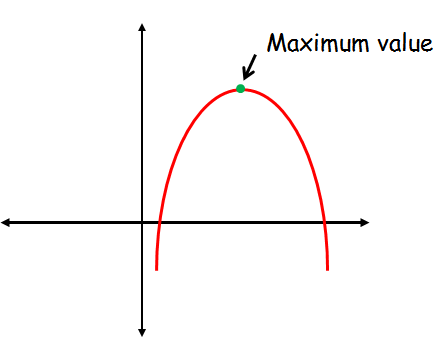

For more complex loading scenarios, such as bending or torsion, the maximum stress formula becomes more intricate. For example, in bending, the maximum stress occurs at the outermost fibers of the beam and is calculated using the flexure formula:

σ = My/I

Where:

- M is the bending moment.

- y is the distance from the neutral axis to the outermost fiber.

- I is the area moment of inertia of the cross-section.

Practical Applications and Case Studies

Understanding and applying the maximum stress formula is crucial in various engineering disciplines. In civil engineering, it's used to design bridges, buildings, and other structures that can withstand various loads and environmental conditions.

In aerospace engineering, it's essential for designing aircraft components that are both lightweight and strong enough to withstand the extreme stresses of flight.

In automotive engineering, it's used to design vehicle chassis, suspension systems, and engine components that can withstand the constant stresses of driving.

Case Study: Bridge Design

Consider a bridge designed to handle heavy traffic. Engineers use the maximum stress formula to calculate the stresses in the bridge's beams and supports under various loading conditions, including the weight of vehicles, wind loads, and seismic activity. By carefully selecting materials and designing the bridge's structure to minimize stress concentrations, engineers can ensure the bridge's safety and longevity.

Factors Affecting Maximum Stress

Several factors can influence the maximum stress a material experiences. These include:

- Material properties: Different materials have different strengths and will withstand different levels of stress.

- Geometry: The shape of the object significantly affects how stress is distributed. Sharp corners, for example, can create stress concentrations.

- Loading conditions: The type, magnitude, and direction of the applied force all play a role.

- Environmental factors: Temperature, humidity, and corrosive environments can weaken materials and reduce their ability to withstand stress.

Advantages and Disadvantages

Advantages:

- Predictive Power: The maximum stress formula allows engineers to predict when a material will fail under load.

- Optimization: It helps optimize designs to use materials efficiently and minimize weight.

- Safety: It ensures structures are safe and reliable.

Disadvantages:

- Simplifications: Formulas often rely on simplified assumptions that may not perfectly reflect real-world conditions.

- Stress Concentrations: Identifying and accurately accounting for stress concentrations can be challenging.

- Material Variability: Material properties can vary, making it difficult to predict failure precisely.

FAQs

What is the difference between stress and pressure?

Stress is an internal force within a material, while pressure is an external force applied over an area. Both are measured in units of force per unit area, but they represent different physical phenomena.

How do I account for stress concentrations in my calculations?

Stress concentrations occur at points where the geometry changes abruptly, such as at holes or corners. To account for them, you can use stress concentration factors, which are empirical values that multiply the nominal stress to estimate the peak stress at the concentration.

What is the factor of safety, and how does it relate to maximum stress?

The factor of safety is a ratio that indicates how much stronger a structure is than it needs to be for an intended load. It's calculated by dividing the material's yield strength or ultimate tensile strength by the maximum stress the structure is expected to experience. A higher factor of safety indicates a more conservative design.

What are some common units used to measure stress?

Common units for measuring stress include Pascals (Pa), megapascals (MPa), pounds per square inch (psi), and kilopounds per square inch (ksi).

How does temperature affect the maximum stress a material can withstand?

Temperature can significantly affect a material's strength. Generally, materials become weaker at higher temperatures, reducing their ability to withstand stress. Conversely, some materials may become stronger at lower temperatures, but also more brittle.

Where can I find reliable material property data for stress calculations?

You can find reliable material property data in handbooks, engineering databases, and material testing reports. Reputable sources include ASM International, Mat Web, and university engineering departments.

Conclusion

The maximum stress formula is a fundamental tool in the field of strength of materials and structural design. By understanding the principles behind it and carefully considering the factors that influence stress, engineers can design safe, efficient, and reliable structures that can withstand the rigors of the real world. So, keep learning, keep calculating, and keep building!

Posting Komentar untuk "Maximum Stress Formula in Strength of Materials"