Maximum Stress Formula for Rotating Shafts Explained

Ever wondered how engineers ensure the spinning shafts in your car, a power plant, or even a simple fan don't just snap under pressure? The secret lies in understanding and applying the maximum stress formula for rotating shafts. These shafts, crucial components in transmitting power, are subject to a complex interplay of forces. Getting the calculations right is not just about performance; it's about safety, reliability, and preventing costly failures. So, let's dive into the world of stress, strain, and rotating shafts to unlock the secrets of structural design.

Understanding the Basics of Stress in Rotating Shafts

Imagine a metal rod spinning at high speed. It might look simple, but within that rod, a battle is raging. Tensile and compressive stresses are constantly pulling and pushing as the material fights to hold itself together. These stresses arise from the torque transmitted through the shaft and the bending moments caused by the forces acting on it. For engineers, understanding these stresses is fundamental to preventing shaft failure, ensuring optimal performance, and building a safer, more reliable world. This is especially important in the field of mechanical engineering.

Stress, in simple terms, is the internal resistance offered by a material to external forces acting on it. It’s usually measured in Pascals (Pa) or pounds per square inch (psi). In rotating shafts, we primarily deal with two types of stress: torsional shear stress, caused by the twisting force (torque), and bending stress, caused by bending moments due to applied loads. These stresses can occur simultaneously, making the analysis slightly complex.

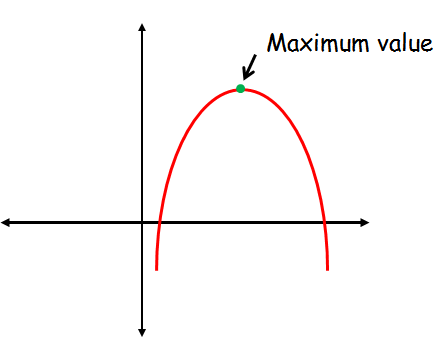

The maximum stress formula helps us determine the highest stress experienced by the shaft material. This information is critical for comparing the calculated stress against the material's yield strength or tensile strength, ensuring the shaft doesn't permanently deform or fracture. The goal is to keep the maximum stress well below the material's limits, incorporating a safety factor to account for uncertainties and variations in material properties and operating conditions.

The Maximum Stress Formula: Derivation and Components

Now, let's get down to the nitty-gritty: the formula itself. The maximum stress (σmax) in a rotating shaft subjected to combined bending and torsion can be expressed as:

σmax = (16 / πd3) √((KbM)2 + (KtT)2)

Where:

- σmax is the maximum stress in the shaft.

- d is the diameter of the shaft.

- M is the bending moment.

- T is the torsional moment (torque).

- Kb is the bending stress concentration factor.

- Kt is the torsional stress concentration factor.

Let's break down each component to understand its role in determining the maximum stress.

Understanding the Components

Shaft Diameter (d): The diameter of the shaft is a critical factor. A larger diameter means a greater cross-sectional area, distributing the stress over a larger area and reducing the overall stress concentration. It's inversely proportional to the cube of the stress, highlighting its significant impact.

Bending Moment (M): Bending moment arises from forces acting perpendicular to the shaft's axis, causing it to bend. The magnitude of the bending moment depends on the magnitude and location of these forces. Accurate determination of bending moments is crucial for precise stress analysis.

Torsional Moment (T): Also known as torque, the torsional moment is the twisting force applied to the shaft. It's directly related to the power transmitted by the shaft and the rotational speed. A higher torque results in higher shear stresses within the shaft.

Stress Concentration Factors (Kb and Kt): These factors account for stress increases at points of geometric discontinuity, such as keyways, holes, or sharp corners. These features disrupt the smooth flow of stress, leading to localized high-stress areas. Kb and Kt are always greater than 1, and their values depend on the geometry of the discontinuity.

Applying the Maximum Stress Formula: A Step-by-Step Guide

Using the formula effectively involves a systematic approach. Here's a step-by-step guide:

- Determine the shaft diameter (d): This is usually given, or it might be the design variable you're trying to find.

- Calculate the bending moment (M): This requires analyzing the forces acting on the shaft and their locations. Draw free-body diagrams to visualize the forces and bending moments.

- Calculate the torsional moment (T): This is determined from the power transmitted by the shaft and its rotational speed using the formula T = (Power x 60) / (2πN), where N is the speed in RPM.

- Determine the stress concentration factors (Kb and Kt): These values are typically obtained from charts or handbooks based on the geometry of the shaft and any stress raisers present (keyways, holes, etc.).

- Plug the values into the formula: Substitute the values of d, M, T, Kb, and Kt into the maximum stress formula.

- Calculate the maximum stress (σmax): Perform the calculation to obtain the maximum stress value.

- Compare with material strength: Compare the calculated maximum stress with the material's yield strength or tensile strength (divided by a safety factor). Ensure that the maximum stress is significantly lower than the allowable stress to prevent failure.

Practical Applications and Case Studies

The maximum stress formula is applied in various real-world scenarios. Let's look at some examples.

Automotive Industry: Drive shafts in vehicles are subjected to significant torsional and bending stresses. Engineers use the maximum stress formula to design shafts that can withstand the high torques generated by the engine and the bending forces due to suspension movements.

Aerospace Engineering: Turbine shafts in jet engines experience extreme conditions, including high temperatures and rotational speeds. Accurate stress analysis is crucial to ensure the structural integrity of these shafts.

Power Generation: Generators in power plants use large rotating shafts to convert mechanical energy into electrical energy. These shafts must be designed to withstand high torques and bending moments to ensure reliable power generation. Structural design and failure analysis are crucial in these scenarios.

Case Study: A wind turbine shaft needs to transmit 2 MW of power at 20 RPM. The shaft has a diameter of 0.5 meters and is made of steel with a yield strength of 350 MPa. Bending moment is calculated to be 50 k Nm, and the stress concentration factors Kb and Kt are

1.5 and

1.2 respectively. By applying the maximum stress formula, engineers can determine if the shaft is safe under these operating conditions. If the calculated maximum stress is significantly less than 350 MPa, the design is considered safe. If not, the shaft diameter or material may need to be adjusted.

Pros and Cons of Using the Maximum Stress Formula

Like any engineering tool, the maximum stress formula has its advantages and limitations.

Pros:

- Relatively simple and straightforward to apply.

- Provides a good estimate of the maximum stress in a shaft.

- Useful for initial design calculations and quick assessments.

Cons:

- Doesn't account for complex loading conditions or stress distributions.

- Relies on accurate determination of bending moments and stress concentration factors.

- May not be suitable for highly complex geometries or materials.

For complex scenarios, finite element analysis (FEA) software provides a more detailed and accurate stress analysis.

Frequently Asked Questions (FAQs)

What is the difference between stress and strain?

Stress is the internal resistance offered by a material to external forces, while strain is the deformation of the material caused by these forces. Stress is proportional to strain within the elastic limit of the material (Hooke's Law).

How do stress concentration factors affect the maximum stress?

Stress concentration factors increase the localized stress at points of geometric discontinuity, such as holes or keyways. This localized stress can be significantly higher than the nominal stress calculated without considering these factors, potentially leading to failure at these points.

Why is it important to include a safety factor when designing rotating shafts?

A safety factor accounts for uncertainties in material properties, loading conditions, and manufacturing tolerances. It ensures that the shaft can withstand stresses beyond the calculated maximum stress, providing a margin of safety to prevent failure.

What are the common causes of failure in rotating shafts?

Common causes of failure include fatigue due to cyclic loading, excessive stress concentrations, corrosion, and material defects. Proper design, material selection, and manufacturing processes can help mitigate these risks.

Can the maximum stress formula be used for shafts made of composite materials?

The maximum stress formula, in its basic form, is primarily intended for isotropic materials like steel. For composite materials, more advanced analysis techniques are required to account for their anisotropic properties and complex failure mechanisms.

How does temperature affect the maximum stress in a rotating shaft?

Temperature can significantly affect the material properties of the shaft, such as its yield strength and tensile strength. Higher temperatures generally reduce these properties, making the shaft more susceptible to failure. Temperature effects should be considered in the stress analysis, especially in high-temperature applications.

Conclusion

The maximum stress formula for rotating shafts is a powerful tool for engineers to design safe and reliable power transmission systems. By understanding the components of the formula and applying it systematically, engineers can ensure that shafts can withstand the stresses imposed on them, preventing costly failures and ensuring optimal performance. While it has limitations, this formula provides a solid foundation for stress analysis and structural design. So, embrace this knowledge, and continue building a world that spins smoothly and safely!

Posting Komentar untuk "Maximum Stress Formula for Rotating Shafts Explained"