Cylinder Stress Formula for Thin-Walled Cylinders

Ever wondered how a massive propane tank manages to hold all that gas without bursting? Or how pipelines carrying oil across vast distances withstand immense pressure? The answer lies in understanding the stresses acting on the walls of these cylindrical structures. Knowing how to calculate these stresses is crucial for ensuring safety and preventing catastrophic failures in many engineering applications.

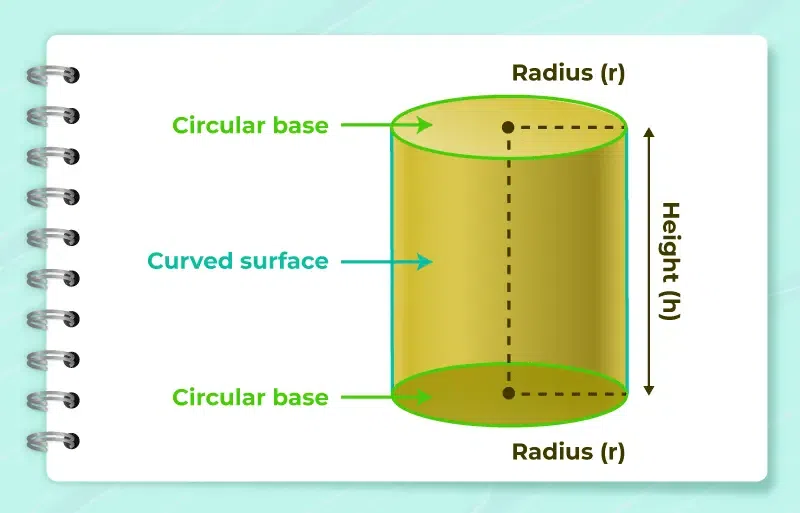

Understanding Thin-Walled Cylinders

Thin-walled cylinders are pressure vessels where the wall thickness is small compared to the diameter. Think of soda cans, pipelines, or even certain aircraft fuselages. The “thin-walled” designation isn’t just arbitrary; it allows us to simplify our stress calculations using specific formulas.

Why does this simplification matter? Because complex, thick-walled cylinder analyses often require finite element methods or more advanced mathematical techniques. For thin-walled cylinders, we can get reasonably accurate stress predictions with much simpler equations, which saves time and resources in initial design phases.

What Defines "Thin-Walled?"

Generally, a cylinder is considered thin-walled if the ratio of its inner radius (r) to its wall thickness (t) is greater than 10 (r/t > 10). This guideline ensures that the stress distribution through the wall thickness is relatively uniform, a key assumption in the thin-walled cylinder theory. When r/t is less than or equal to 10, the cylinder should be treated as "thick-walled", requiring more complex analysis techniques.

Types of Stress in Thin-Walled Cylinders

Thin-walled cylinders under internal pressure experience two primary types of stress: hoop stress (also known as circumferential stress) and longitudinal stress (also known as axial stress).

Hoop stress acts tangentially to the cylinder's circumference, essentially trying to split the cylinder lengthwise. Longitudinal stress acts along the axis of the cylinder, trying to pull the ends apart. Understanding both is crucial for comprehensive structural design.

Hoop Stress (σh)

Hoop stress is caused by the internal pressure acting radially outwards. Imagine tiny forces pushing outward, trying to expand the cylinder's circumference. This is where the strength of the material really gets tested.

The formula for hoop stress in a thin-walled cylinder is: σh = (p r) / t

Where:

- σh is the hoop stress

- p is the internal pressure

- r is the inner radius of the cylinder

- t is the wall thickness of the cylinder

Longitudinal Stress (σl)

Longitudinal stress arises from the internal pressure acting on the end caps of the cylinder. This pressure creates a force that tries to stretch the cylinder along its length.

The formula for longitudinal stress in a thin-walled cylinder is: σl = (p r) / (2 t)

Notice that the longitudinal stress is half the hoop stress. This means that the cylinder is more likely to fail due to hoop stress than longitudinal stress, assuming the material is equally strong in both directions.

The Cylinder Stress Formula in Action: Examples

Let's solidify our understanding with a couple of examples. These are simplified scenarios, but they'll help illustrate how the formulas are applied in practice. These examples will deal with tensile and compressive stress. Failure analysis depends on accurate calculations of stress.

Example 1: Propane Tank

A cylindrical propane tank has an inner radius of 0.5 meters and a wall thickness of

0.01 meters. If the internal pressure is 2 MPa (Mega Pascals), calculate the hoop and longitudinal stresses.

First, let's calculate the hoop stress:

σh = (p r) / t = (2 MPa 0.5 m) /

0.01 m = 100 MPa

Now, let's calculate the longitudinal stress:

σl = (p r) / (2 t) = (2 MPa 0.5 m) / (2

0.01 m) = 50 MPa

The hoop stress is 100 MPa, and the longitudinal stress is 50 MPa. This tells engineers that the tank needs to be designed to withstand at least 100 MPa in the hoop direction to prevent failure.

Example 2: Pipeline

An oil pipeline has an inner diameter of 1 meter (radius = 0.5 meters) and a wall thickness of

0.008 meters. The internal pressure due to the oil flow is 5 MPa. Determine the hoop and longitudinal stresses.

Hoop Stress:

σh = (p r) / t = (5 MPa 0.5 m) /

0.008 m =

312.5 MPa

Longitudinal Stress:

σl = (p r) / (2 t) = (5 MPa 0.5 m) / (2

0.008 m) =

156.25 MPa

In this case, the pipeline is subjected to a hoop stress of 312.5 MPa and a longitudinal stress of

156.25 MPa. The pipe material selection and welding quality must be carefully considered to handle these significant stress levels.

Practical Applications and Considerations

The cylinder stress formula finds use in numerous industries. Mechanical engineering, aerospace engineering, civil engineering, and the oil and gas industry are some examples. Whenever cylindrical pressure vessels are involved, these principles apply.

Beyond the simple calculations, several factors require consideration in real-world applications.

- Material Properties: The formulas assume the material is homogeneous and isotropic (properties are the same in all directions). This isn't always the case.

- Corrosion: Over time, corrosion can thin the walls, increasing stress levels. Regular inspections are crucial.

- Welding: Welds are often the weakest points. Proper welding techniques and non-destructive testing are essential.

- External Loads: The formulas only consider internal pressure. External loads (weight, wind, etc.) can significantly alter stress distributions.

Pros and Cons of Using Thin-Walled Cylinder Theory

Like any simplified model, the thin-walled cylinder theory has its advantages and limitations.

Pros

- Simplicity: The formulas are easy to understand and apply.

- Speed: Calculations are quick, making them ideal for initial design estimations.

- Cost-Effective: Reduces the need for complex analysis in preliminary stages.

Cons

- Accuracy Limitations: The theory is less accurate for cylinders with thicker walls (r/t < 10).

- Simplified Assumptions: Ignores stress concentrations and other complex loading scenarios.

- Material Homogeneity: Assumes uniform material properties, which may not always hold true.

Frequently Asked Questions

When should I use the thin-walled cylinder formula versus a thick-walled cylinder formula?

Use the thin-walled cylinder formula when the ratio of the cylinder's inner radius to its wall thickness (r/t) is greater than 10. If r/t is less than or equal to 10, a thick-walled cylinder analysis is more appropriate for accurate stress calculations.

What are the common units used in the cylinder stress formula?

Pressure (p) is commonly measured in Pascals (Pa) or Mega Pascals (MPa). Radius (r) and thickness (t) are typically measured in meters (m) or millimeters (mm). The resulting stress (σ) will be in the same units as the pressure (Pa or MPa).

What does a high hoop stress value indicate?

A high hoop stress value indicates that the cylinder's circumference is under significant tension and is at a higher risk of rupturing. This means either the pressure is too high, the radius is too large, or the wall thickness is insufficient to withstand the pressure.

How does temperature affect stress in thin-walled cylinders?

Temperature changes can induce thermal stresses in the cylinder walls due to thermal expansion or contraction. If the cylinder is constrained, these temperature-induced strains can result in significant stresses, which need to be considered in the design.

Can I use the cylinder stress formula for non-cylindrical pressure vessels?

No, the thin-walled cylinder formula is specifically derived for cylindrical geometries. For non-cylindrical pressure vessels, such as spherical or ellipsoidal tanks, different stress formulas and analysis techniques are required.

What safety factor should I apply to the calculated stress values?

The safety factor depends on the application, material properties, and regulatory requirements. It's generally a value greater than 1 (e.g., 2, 3, or higher) and is used to ensure that the actual stress in the cylinder remains well below the material's yield strength or ultimate tensile strength, providing a margin of safety against failure.

Conclusion

Understanding the cylinder stress formula for thin-walled cylinders is fundamental for engineers and anyone involved in the design and analysis of pressure vessels. By grasping the concepts of hoop and longitudinal stress, and considering the limitations of the thin-walled theory, you can make informed decisions to ensure the safety and reliability of these critical structures. Keep practicing, stay curious, and never stop exploring the fascinating world of structural mechanics!

Posting Komentar untuk "Cylinder Stress Formula for Thin-Walled Cylinders"