Max Stress Formula in Pressure Vessels and Cylinders

Ever wondered how submarines withstand immense underwater pressure, or how gas cylinders safely store highly compressed fuel? The secret lies in understanding and calculating the maximum stress within these pressure vessels. Ignoring this can lead to catastrophic failures, making it a critical area in mechanical engineering. For students, engineers, and professionals involved in structural design and failure analysis, mastering the max stress formula is non-negotiable. This guide provides a deep dive into this essential concept.

Understanding Pressure Vessels and Stress

Pressure vessels are closed containers designed to hold liquids, gases, or vapors at pressures different from ambient pressure. These vessels range from small compressed air tanks to massive nuclear reactor vessels. Cylinders, a specific type of pressure vessel, are commonly used for storing gases like propane and oxygen. The primary concern in their design is ensuring they can withstand the internal pressure without yielding or fracturing.

When internal pressure is applied, the vessel's walls experience stress. Stress, in this context, is the internal resistance offered by the material to the external force (pressure) causing deformation. We're specifically interested in themaximumstress, as this is the point where failure is most likely to initiate. Calculating this accurately is paramount for safe and efficient design.

Types of Stress in Cylindrical Pressure Vessels

Cylindrical pressure vessels primarily experience two types of stress: hoop stress (also called circumferential stress) and longitudinal stress (also called axial stress). Understanding the direction and magnitude of each is crucial for applying the correct formula.

Hoop stress acts tangentially around the circumference of the cylinder, essentially trying to split the cylinder along its length. Imagine cutting a ring from the cylinder; hoop stress resists this separation.

Longitudinal stress acts along the axis of the cylinder, trying to pull the cylinder apart end-to-end. Think of it as the force that would try to separate the cylinder's two end caps.

The Max Stress Formula: A Detailed Look

Now, let’s delve into the formulas for calculating these stresses, which will ultimately lead us to determining the maximum stress. Knowing these equations is fundamental to structural design and ensuring material strength under pressure.

Hoop Stress Formula

The formula for hoop stress (σh) in a thin-walled cylindrical pressure vessel is:

σh = (P r) / t

Where:

- P = Internal pressure

- r = Internal radius of the cylinder

- t = Wall thickness of the cylinder

This formula tells us that hoop stress is directly proportional to the internal pressure and radius, and inversely proportional to the wall thickness. A thicker wall or smaller radius reduces the hoop stress.

Longitudinal Stress Formula

The formula for longitudinal stress (σl) in a thin-walled cylindrical pressure vessel is:

σl = (P r) / (2 t)

Notice that this is exactly half the hoop stress. This means that, for a cylindrical pressure vessel, the hoop stress is always the dominant stress. Therefore, the maximum stress in most cases is simply the hoop stress.

Determining Max Stress

In a thin-walled cylinder, the maximum stress is typically the hoop stress because it is twice the longitudinal stress. However, it's essential to consider other factors like stress concentrations at openings or welds. In such cases, finite element analysis (FEA) might be necessary for a more accurate assessment.

Therefore, for practical purposes and initial calculations, the max stress (σmax) can be approximated as:

σmax ≈ σh = (P r) / t

Practical Application and Example

Let's consider a practical example to solidify your understanding. Suppose we have a propane tank with an internal radius of 0.5 meters and a wall thickness of

0.01 meters. The tank is designed to hold propane at a pressure of 2 MPa (Mega Pascals).

First, calculate the hoop stress:

σh = (2 MPa 0.5 m) /

0.01 m = 100 MPa

Next, calculate the longitudinal stress:

σl = (2 MPa 0.5 m) / (2

0.01 m) = 50 MPa

In this case, the maximum stress is approximately 100 MPa, the hoop stress. We would then compare this value to the yield strength and tensile strength of the tank's material to ensure an adequate safety factor.

Factors Affecting Max Stress

Several factors beyond internal pressure and dimensions influence the maximum stress. These include:

- Material Properties: The yield strength and tensile strength of the material determine its ability to withstand stress before permanent deformation or fracture.

- Temperature: Elevated temperatures can reduce the material's strength, making it more susceptible to failure.

- Corrosion: Corrosion can thin the vessel walls, increasing stress levels and creating stress concentrations.

- Welding: Improper welding techniques can introduce defects that act as stress concentrators.

- External Loads: Additional loads, such as the weight of the vessel's contents or external forces, can contribute to the overall stress.

Benefits and Limitations of the Formula

The max stress formula provides a quick and easy way to estimate stress levels in cylindrical pressure vessels. This is especially useful during initial design phases or for quick checks. However, it has limitations:

Benefits:

- Simplicity: Easy to understand and apply.

- Speed: Provides a rapid estimate of stress levels.

- Cost-effective: Requires minimal resources compared to advanced analysis techniques.

Limitations:

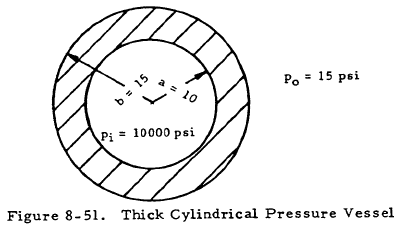

- Thin-walled Assumption: Accurate only for thin-walled vessels (typically when the diameter-to-thickness ratio is greater than 10).

- Simplified Geometry: Does not account for complex geometries or stress concentrations.

- Static Loading: Assumes static internal pressure; it doesn't account for dynamic loads or fatigue.

For more complex scenarios, finite element analysis (FEA) software provides a more comprehensive assessment of stress distribution and potential failure points. FEA can handle complex geometries, variable loads, and material nonlinearities.

Case Studies

Numerous real-world examples demonstrate the importance of accurately calculating maximum stress:

- The Comet Air Disasters: Early jet airliners suffered from square windows that created stress concentrations, leading to catastrophic fatigue failures.

- Pipeline Explosions: Corrosion and defects in pipelines can lead to increased stress and eventual rupture, causing environmental damage and safety hazards.

- Boiler Explosions: Overpressure in boilers, often due to malfunctions or inadequate maintenance, can result in violent explosions.

These incidents underscore the necessity of rigorous design, inspection, and maintenance protocols for pressure vessels and cylinders.

FAQs

What is the difference between hoop stress and longitudinal stress?

Hoop stress acts circumferentially around the cylinder, while longitudinal stress acts along the axis of the cylinder. Hoop stress is typically twice the magnitude of longitudinal stress in cylindrical pressure vessels.

When is the thin-walled assumption valid?

The thin-walled assumption is valid when the ratio of the cylinder's diameter to its wall thickness is greater than 10. For thicker-walled vessels, more complex stress analysis methods are required.

What are stress concentrations, and how do they affect maximum stress?

Stress concentrations are localized areas of higher stress, often occurring at geometric discontinuities such as holes, corners, or welds. These concentrations can significantly increase the maximum stress and increase the risk of failure.

How does temperature affect the maximum stress in a pressure vessel?

Elevated temperatures can reduce the material's yield strength and tensile strength, making it more susceptible to failure under stress. Conversely, low temperatures can make some materials brittle.

What is a safety factor, and why is it important in pressure vessel design?

A safety factor is a multiplier applied to the calculated maximum stress to account for uncertainties in material properties, manufacturing processes, and operating conditions. It ensures that the vessel can withstand stresses beyond its design limits without failing.

Can finite element analysis (FEA) be used to calculate maximum stress?

Yes, FEA is a powerful tool for calculating maximum stress in complex pressure vessel geometries and loading conditions. It can account for stress concentrations, material nonlinearities, and dynamic loads, providing a more accurate and comprehensive assessment of stress distribution.

Conclusion

Understanding the max stress formula is essential for anyone involved in the design, analysis, or maintenance of pressure vessels and cylinders. While the basic formulas provide a good starting point, it's important to consider all influencing factors and, when necessary, utilize advanced analysis techniques like FEA. By prioritizing safety and accuracy, we can prevent catastrophic failures and ensure the reliable performance of these critical components. Mastering these principles will not only make you a better engineer but also contribute to a safer world.

Posting Komentar untuk "Max Stress Formula in Pressure Vessels and Cylinders"