Common Engineering Materials and Their Ultimate Stress Formula

Ever wondered why a bridge can withstand the weight of countless cars, or why an airplane doesn't simply fall apart mid-flight? The secret lies in the careful selection and understanding of engineering materials, and a crucial concept called "ultimate stress." For engineers, students, and anyone involved in structural design, knowing which materials to use and how much stress they can handle is not just important, it's paramount for safety and success.

Understanding Ultimate Stress

Ultimate stress, also known as ultimate tensile strength (UTS), represents the maximum stress a material can withstand before it begins to fracture or break. It’s a critical parameter in mechanical engineering and structural design. Understanding this value ensures that structures are built to withstand anticipated loads and prevent catastrophic failures.

In simpler terms, imagine stretching a rubber band. You can pull it further and further until, eventually, it snaps. The amount of force per unit area just before the rubber band breaks is its ultimate stress. For engineers, this "breaking point" is a critical design factor.

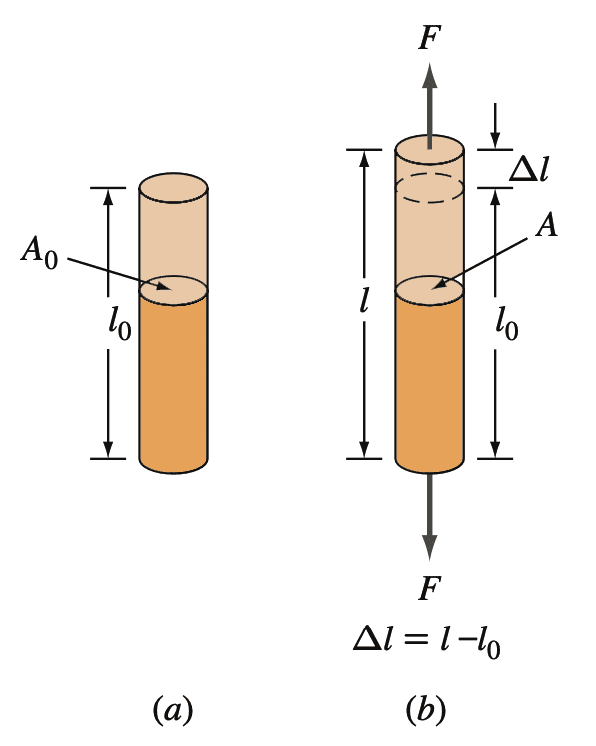

Defining Stress

Stress (σ) is defined as the force (F) acting per unit area (A) of a material. Mathematically, it's expressed as: σ = F/A. Stress can be tensile (pulling), compressive (pushing), or shear (sliding).

The Ultimate Stress Formula

While the formula for stress is straightforward (σ = F/A), determining theultimatestress of a material typically involves experimental testing. A common method is the tensile test, where a specimen of the material is subjected to a controlled tensile force until it fractures. The highest stress value recorded during the test is the ultimate tensile strength.

Therefore, the "ultimate stress formula" isn't a calculation you perform tofindultimate stress. It’s using the stress formula (σ = F/A) in conjunction withexperimentally determinedvalues to ensure the applied stress remains below the material's known ultimate stress. So, knowing the ultimate stress of a material allows you to calculate the maximum force a component of a specific cross-sectional area can withstand before failure.

Common Engineering Materials and Their Properties

Different materials possess vastly different ultimate stress values. Here's a look at some common engineering materials and their typical ultimate tensile strength, keeping in mind that values can vary based on alloy composition, heat treatment, and other factors.

Steel

Steel is a widely used engineering material due to its high strength-to-weight ratio and relatively low cost. Different types of steel exist, each with varying ultimate tensile strengths. For example, mild steel has a lower UTS than high-strength alloy steel.

Pros: High strength, readily available, relatively inexpensive.

Cons: Susceptible to corrosion (rust), can be heavy.

Aluminum

Aluminum is known for its lightweight and corrosion resistance. While its ultimate tensile strength is generally lower than steel, its lighter weight makes it ideal for applications where weight is a critical factor, such as in aerospace.

Pros: Lightweight, corrosion resistant, good conductivity.

Cons: Lower strength than steel, more expensive than steel.

Concrete

Concrete is a composite material widely used in construction. It's strong in compression but weak in tension. This is why steel reinforcement is often used in concrete structures to enhance their tensile strength.

Pros: High compressive strength, readily available, relatively inexpensive.

Cons: Low tensile strength, can crack easily without reinforcement.

Polymers

Polymers (plastics) are versatile materials with a wide range of properties. Their ultimate tensile strength varies significantly depending on the type of polymer. Some polymers are strong and rigid, while others are flexible and elastic.

Pros: Lightweight, corrosion resistant, can be molded into complex shapes.

Cons: Lower strength than metals, can be susceptible to temperature changes.

Wood

Wood, a natural composite material, has been used in construction for centuries. Its strength varies depending on the species and grain direction. It's generally stronger along the grain than across it.

Pros: Renewable resource, relatively inexpensive, good strength-to-weight ratio (for some species).

Cons: Susceptible to rot and insect damage, strength varies significantly, flammable.

Practical Applications and Case Studies

Understanding ultimate stress is crucial in numerous engineering applications. Consider these examples:

Bridge Design: Civil engineers carefully select materials and design bridge structures to ensure that the stresses induced by traffic and environmental factors remain well below the materials' ultimate stress. Aircraft Manufacturing: Aerospace engineers use lightweight materials like aluminum and composites, but must meticulously calculate stress levels to ensure the aircraft can withstand the forces of flight. Automotive Engineering: Automotive engineers consider ultimate stress when designing vehicle frames, suspension components, and engine parts to ensure safety and durability. Building Construction: Architects and structural engineers specify materials with appropriate ultimate stress values for columns, beams, and foundations to prevent structural collapse.

Case Study: The Tacoma Narrows Bridge: A famous example of what happens when material properties and stress are underestimated is the Tacoma Narrows Bridge collapse in 1940. While not directly related to exceeding ultimate stress, the bridge's design failed to account for aerodynamic forces that induced excessive oscillations, ultimately leading to structural failure. This highlights the importance of considering all potential stressors and material limits in design.

Factors Affecting Ultimate Stress

Several factors can influence a material's ultimate stress:

Temperature: Higher temperatures generally reduce a material's ultimate stress. Material Composition: Alloying elements can significantly affect a material's strength. Manufacturing Processes: Heat treatment, cold working, and other manufacturing processes can alter a material's microstructure and, consequently, its ultimate stress. Environmental Conditions: Exposure to corrosive environments can degrade a material's strength over time.

Safety Factors

Because of the variables that affect ultimate stress, engineers almost always design structures using a "safety factor." This involves designing components to withstand loads significantly higher than those expected in normal operation. The safety factor accounts for uncertainties in material properties, manufacturing tolerances, and service conditions, ensuring a margin of safety against failure.

Conclusion

Understanding common engineering materials and their ultimate stress is fundamental to safe and effective structural design. By carefully considering material properties, applying appropriate safety factors, and accounting for potential stressors, engineers can create structures that are both strong and durable. Remember, knowing the limits of your materials is the key to building a world that lasts.

Frequently Asked Questions

What is the difference between ultimate stress and yield strength?

Yield strength is the point at which a material begins to deform permanently. Ultimate stress is the maximum stress a material can withstand before it breaks. A material can deform significantly after reaching its yield strength, but before reaching its ultimate stress.

How is ultimate stress determined?

Ultimate stress is typically determined through experimental testing, most commonly a tensile test. A specimen is subjected to a controlled tensile force until it fractures, and the highest stress value recorded is the ultimate tensile strength.

Why is a safety factor important in engineering design?

A safety factor accounts for uncertainties in material properties, manufacturing tolerances, and service conditions. It provides a margin of safety against failure, ensuring that structures can withstand unexpected loads or environmental changes.

Can ultimate stress values be found in material data sheets?

Yes, material data sheets typically list the ultimate tensile strength (UTS) of a material. However, it's important to note that these values are often based on standard testing conditions and may vary depending on the specific application and environmental factors.

How does temperature affect ultimate stress?

Generally, higher temperatures reduce a material's ultimate stress. This is because increased temperature can weaken the bonds between atoms in the material, making it easier to deform or fracture.

Is ultimate stress the only factor to consider in material selection?

No. While ultimate stress is a critical factor, other considerations include yield strength, fatigue resistance, corrosion resistance, cost, weight, and manufacturability. The specific requirements of the application will dictate the most important material properties.

Posting Komentar untuk "Common Engineering Materials and Their Ultimate Stress Formula"