Thermal Stress Formula in Daily Life Engineering Problems

Ever wondered why bridges have expansion joints or why your phone feels warm after prolonged use? The answer often lies in thermal stress – a phenomenon that’s far more common than you might think. For engineers, understanding and calculating thermal stress is crucial for designing safe and reliable structures and products. Neglecting it can lead to catastrophic failures. This article will break down the thermal stress formula and show you how it applies to everyday engineering challenges.

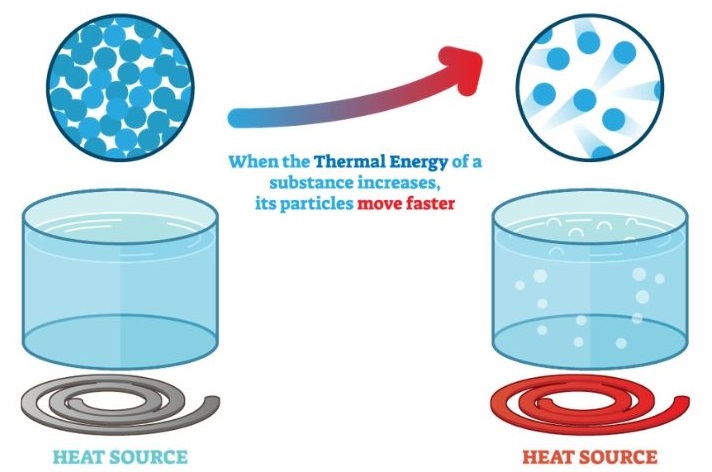

Understanding Thermal Stress

Thermal stress arises when a material is subjected to temperature changes and constrained from expanding or contracting freely. This constraint generates internal stresses within the material. Think of a metal rod fixed at both ends; when heated, it tries to expand, but the fixed ends prevent it. This creates compressive stress within the rod. Similarly, cooling a constrained material induces tensile stress.

These stresses can accumulate and, if not properly accounted for in the structural design, lead to material failure. Thermal stress is a critical consideration in mechanical engineering, civil engineering, and even smaller-scale designs like electronics.

The Thermal Stress Formula Explained

The thermal stress formula quantifies this relationship:

σ = α E ΔT

Where:

- σ (sigma) represents the thermal stress (typically in Pascals or PSI).

- α (alpha) is the coefficient of thermal expansion of the material (typically in 1/°C or 1/°F). This value indicates how much a material expands or contracts per degree of temperature change.

- E is the Young's modulus of the material (typically in Pascals or PSI), representing the material's stiffness or resistance to deformation.

- ΔT (Delta T) is the change in temperature (typically in °C or °F).

It's a simple formula, but its implications are profound. Let's delve into each component further.

Coefficient of Thermal Expansion (α)

Different materials expand and contract at different rates when subjected to temperature variations. Aluminum expands much more than steel for the same temperature change. The coefficient of thermal expansion (α) is a material property that quantifies this behavior. A higher α means a greater change in size for a given temperature change. Reference tables provide α values for various materials; it's crucial to use the correct value for your chosen material in any thermal stress calculation. Ignoring this can lead to significant errors in your failure analysis.

Young's Modulus (E)

Young's modulus, also known as the modulus of elasticity, measures a material's stiffness. A higher Young's modulus indicates a stiffer material that requires more force to deform. Materials with high Young's modulus will experience higher thermal stresses for the same temperature change compared to more flexible materials, assuming all other factors are constant. Steel, for example, has a much higher Young’s modulus than rubber.

Temperature Change (ΔT)

The greater the temperature change (ΔT), the greater the thermal stress. This might seem obvious, but understanding the range of temperature variations a structure will experience is crucial for accurate design. Consider the difference in temperature swings for a bridge in Alaska versus one in Florida; the Alaskan bridge needs to be designed to withstand significantly larger ΔT values.

Practical Applications of the Thermal Stress Formula

The thermal stress formula isn’t just a theoretical concept; it's actively used to solve problems and design safer products.

Bridge Design

Bridges are exposed to significant temperature variations throughout the year. Engineers use the thermal stress formula to calculate the expansion and contraction of bridge decks and support structures. Expansion joints are incorporated into the design to accommodate these movements, preventing the buildup of excessive thermal stress that could lead to cracking or collapse. Ignoring thermal stress in bridge design can have disastrous consequences. Civil engineering thoroughly utilizes these concepts.

Piping Systems

Piping systems that transport hot or cold fluids are also susceptible to thermal stress. Expansion loops or bellows are often included to allow the pipes to expand and contract without putting undue stress on the connections or supporting structures. Material strength calculations are essential for designing such systems.

Electronics

Electronic components generate heat during operation. This heat can cause thermal stress in the components themselves and in the circuit boards they are mounted on. Engineers use thermal analysis and the thermal stress formula to design cooling systems and select materials with appropriate thermal expansion properties to minimize stress and prevent premature failure of electronic devices. Even small temperature changes can affect the longevity of sensitive electronics.

Case Study: Bimetallic Strip

A bimetallic strip is a classic example of thermal expansion in action. It consists of two different metals with different coefficients of thermal expansion bonded together. When heated, the metal with the higher coefficient of thermal expansion expands more than the other, causing the strip to bend. This principle is used in thermostats, circuit breakers, and other temperature-sensitive devices.

Pros and Cons of Considering Thermal Stress

Addressing thermal stress in design offers numerous benefits, but also presents some challenges.

Pros:

- Increased Safety: Prevents structural failures and ensures the safety of people and equipment.

- Improved Reliability: Extends the lifespan of structures and components by minimizing stress-related damage.

- Optimized Design: Allows for more efficient use of materials by accounting for thermal effects.

Cons:

- Increased Complexity: Requires more detailed analysis and calculations, adding to the design process.

- Higher Costs: May necessitate the use of more expensive materials or design features to accommodate thermal expansion and contraction.

Step-by-Step Calculation Example

Let's say we have a steel beam 10 meters long that experiences a temperature change of 50°C. The coefficient of thermal expansion for steel is 12 x 10-6 /°C, and its Young's modulus is 200 GPa (200 x 109 Pa). If the beam is constrained from expanding, what is the thermal stress?

Step 1: Identify the given values.

α = 12 x 10-6 /°C

E = 200 x 109 Pa

ΔT = 50°C

Step 2: Apply the formula.

σ = α E ΔT

σ = (12 x 10-6 /°C) (200 x 109 Pa) (50°C)

Step 3: Calculate the thermal stress.

σ = 120 x 106 Pa

σ = 120 MPa

Therefore, the thermal stress in the steel beam is 120 MPa. This highlights the significant stress levels that can arise from even moderate temperature changes.

Thermal Stress vs. Other Types of Stress

It's important to distinguish thermal stress from other types of stress, such as mechanical stress (caused by external forces) and residual stress (stress present in a material even without external loads or temperature changes). While all these stresses can contribute to material failure, thermal stress is unique in that it is directly related to temperature changes and material properties.

FAQ Section

What happens if thermal stress exceeds the material's yield strength?

If the thermal stress exceeds the material's yield strength, the material will undergo permanent deformation. If it exceeds the ultimate tensile strength, the material will fracture.

How can I reduce thermal stress in a design?

Several strategies can reduce thermal stress, including using materials with lower coefficients of thermal expansion, incorporating expansion joints or loops, and designing cooling systems to minimize temperature variations.

Is thermal stress more significant in certain materials?

Yes, materials with high coefficients of thermal expansion and high Young's moduli are more susceptible to thermal stress.

Does the size of the object affect thermal stress?

While the size of the object doesn't directly appear in the thermal stress formula, it can influence the magnitude of the temperature change (ΔT) experienced by the object, which indirectly affects the thermal stress.

Can thermal stress be beneficial?

In some cases, thermal stress can be used to create beneficial effects, such as in shrink-fitting processes where one component is heated to expand it before being fitted onto another component. As it cools, the thermal stress creates a tight fit.

What software tools are available for analyzing thermal stress?

Various FEA (Finite Element Analysis) software packages like ANSYS, Abaqus, and COMSOL are used to simulate and analyze thermal stress in complex geometries and loading conditions.

Conclusion

The thermal stress formula is a fundamental tool for engineers in various disciplines. By understanding the principles behind it and its practical applications, engineers can design safer, more reliable, and more durable structures and products. Remember to consider the coefficient of thermal expansion, Young’s modulus, and the expected temperature variations in your designs. Don't underestimate the impact of thermal stress—it's a critical factor in ensuring the longevity and safety of everything around us. Master this formula, and you’ll be well-equipped to tackle real-world engineering problems with confidence.

Posting Komentar untuk "Thermal Stress Formula in Daily Life Engineering Problems"