Derivation of Yield Stress Formula in Strength of Materials

Ever wondered how engineers ensure a bridge can withstand heavy traffic or an aircraft wing can handle extreme forces? It all boils down to understanding a material's yield strength – a critical property that dictates when a material begins to deform permanently. Mastering the yield stress formula is essential for anyone involved in mechanical engineering, structural design, or failure analysis.

Understanding Yield Stress

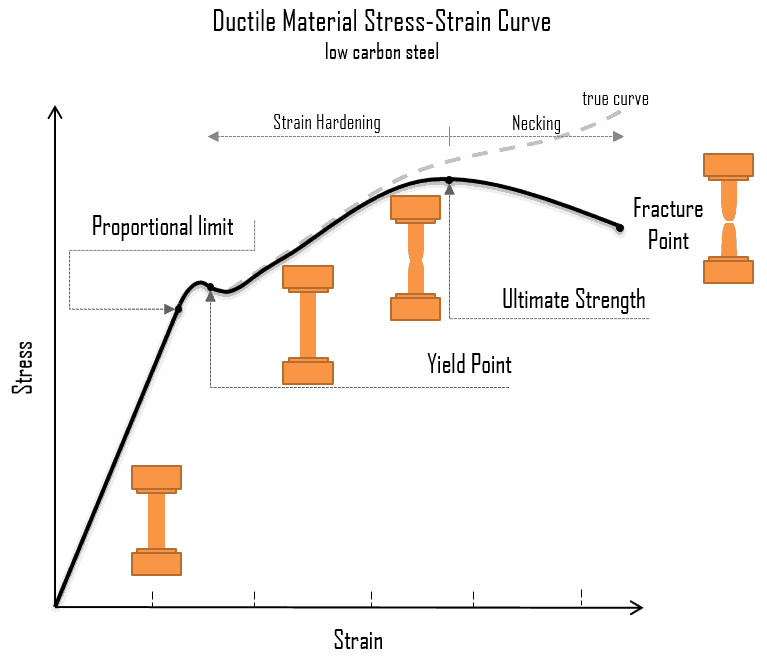

Yield stress is the point at which a material begins to deform plastically. Before reaching the yield point, the material behaves elastically, meaning it will return to its original shape once the load is removed. However, once the yield stress is exceeded, the material undergoes permanent deformation. Understanding and calculating yield stress is crucial for preventing structural failures.

In practical terms, imagine bending a paperclip. Initially, it springs back to its original shape (elastic deformation). But if you bend it far enough, it stays bent (plastic deformation). The point where it starts to stay bent is related to its yield strength. For designers, that "staying bent" point can be catastrophic for a structure.

Defining Key Terms

Before diving into the formula, let's define some key terms:

Stress (σ): Force applied per unit area. Measured in Pascals (Pa) or pounds per square inch (psi). Mathematically, Stress = Force / Area. Strain (ε): The deformation of a material caused by stress. It is dimensionless and represents the change in length divided by the original length. Strain = Change in Length / Original Length. Yield Strength (σy):The stress at which a material begins to deform plastically.

Deriving the Yield Stress Formula

The "formula" for yield stress isn't a single, simple equation like E=mc². Instead, it’s determined experimentally through a tensile test. A tensile test involves gradually applying a load to a specimen and measuring the resulting stress and strain. The data is then plotted on a stress-strain curve.

The yield strength is identified on the stress-strain curve using the "offset method." A line is drawn parallel to the linear (elastic) portion of the curve, offset by a standard strain value, typically 0.2% (0.002). The point where this offset line intersects the stress-strain curve is considered the yield strength.

Steps to Determine Yield Stress from a Stress-Strain Curve

Here's a step-by-step guide to determining yield stress from a stress-strain curve:

1.Obtain a Stress-Strain Curve: Perform a tensile test on the material and plot the data to create a stress-strain curve.

2.Identify the Linear Region: Locate the initial, straight portion of the curve, which represents the elastic region.

3.Draw the Offset Line: Draw a line parallel to the linear region, offset by a strain of

0.002 (0.2%). Start this line at the

0.002 strain point on the x-axis (strain axis).

4.Find the Intersection: Determine the point where the offset line intersects the stress-strain curve.

5.Read the Yield Strength: Read the stress value at the intersection point. This value represents the yield strength (σy) of the material.

Mathematical Representation

While there's no direct formula for yield stress, we use the following relationship to understand its position on the stress-strain curve:

σy = Stress at (Strain = 0.002 + Strain at the origin of the linear region)

Essentially, we're finding the stress corresponding to a specific strain value that's offset from the elastic region.

Practical Applications of Yield Stress

Yield stress plays a vital role in various engineering applications:

Structural Design: Engineers use yield stress to ensure that structures like bridges, buildings, and dams can withstand applied loads without permanent deformation. Material Selection: When choosing materials for a specific application, engineers consider the yield strength to ensure it meets the required performance criteria. Manufacturing Processes: Yield stress is important in processes like forging, rolling, and extrusion, where materials are intentionally deformed. Failure Analysis: Understanding the yield strength of a material helps in analyzing the causes of structural failures and preventing future incidents.

Case Study: Bridge Design

Consider a bridge designed to support heavy traffic. Engineers must select steel with a yield strength high enough to prevent the bridge from sagging permanently under the weight of vehicles. By using appropriate safety factors and calculating the expected stresses, they can ensure the bridge remains safe and functional throughout its lifespan. This involves complex calculations, but the starting point is knowing the yield strength of the steel.

Advantages and Limitations

Advantages:

Provides a critical benchmark for material behavior under load.

Enables engineers to design safe and reliable structures.

Facilitates material selection for specific applications.

Limitations:

Yield stress is temperature-dependent; values obtained at room temperature may not be applicable at elevated or cryogenic temperatures.

The offset method is an approximation; other methods may be used for materials with less defined yield points.

Doesn't account for creep (time-dependent deformation under constant stress) or fatigue (failure due to repeated loading).

Comparing Yield Strength to Other Material Properties

It’s important to distinguish yield strength from other material properties like:

Tensile Strength (Ultimate Tensile Strength): The maximum stress a material can withstand before it starts to neck down (localize deformation) and eventually fracture. Tensile strength ishigherthan yield strength. Elastic Modulus (Young's Modulus): A measure of a material's stiffness or resistance to elastic deformation. Hardness:A material's resistance to localized plastic deformation, typically measured by indentation.

While all these properties are important, yield strength is particularly crucial for preventing permanent deformation in structural applications.

Frequently Asked Questions

What is the difference between yield strength and tensile strength?

Yield strength is the stress at which a material begins to deform permanently, while tensile strength is the maximum stress a material can withstand before it starts to fracture. Tensile strength is always higher than yield strength.

Why is the 0.2% offset method used to determine yield strength?

The 0.2% offset method is a standardized way to define the yield strength for materials that don't have a clearly defined yield point on their stress-strain curve. It provides a consistent and repeatable measure of the material's resistance to plastic deformation.

How does temperature affect yield strength?

Generally, yield strength decreases as temperature increases. At higher temperatures, materials become more ductile and require less stress to deform permanently. Conversely, at lower temperatures, materials become more brittle and have higher yield strengths, but may also be more prone to fracture.

Can yield strength be calculated theoretically?

While theoretical models exist, yield strength is primarily determined experimentally through tensile testing. Theoretical models can provide estimates, but experimental validation is crucial for accurate determination of yield strength.

Is yield strength the only factor to consider in structural design?

No, yield strength is just one of many factors to consider. Other important factors include tensile strength, fatigue strength, creep resistance, corrosion resistance, and the overall loading conditions. A comprehensive design approach considers all these factors to ensure structural integrity.

What are some common materials with high yield strengths?

High-strength steels, titanium alloys, and certain aluminum alloys are known for their high yield strengths. These materials are commonly used in applications where high strength-to-weight ratios and resistance to permanent deformation are critical.

Conclusion

Understanding the derivation and application of the yield stress formula is fundamental for engineers involved in designing and analyzing structures. While the determination involves experimental methods and interpreting stress-strain curves, grasping the underlying principles is essential for ensuring the safety and reliability of engineered systems. So, keep exploring, keep testing, and keep building a stronger, safer world!

Posting Komentar untuk "Derivation of Yield Stress Formula in Strength of Materials"