Torsional Stress Formula Explained with Solved Problems

Ever wonder what keeps the driveshaft in your car from twisting itself apart when you floor the accelerator? Or how engineers design bridges that can withstand relentless twisting forces from wind and traffic? The answer lies in understanding torsional stress, a critical concept in mechanical engineering that governs the behavior of materials under twisting loads.

For engineers, students, and anyone involved in structural design, failure analysis, or material science, mastering the torsional stress formula is essential. It allows us to predict how a component will respond to torque, ensuring safety, reliability, and optimal performance. Let's dive into the details and equip you with the knowledge to confidently tackle torsional stress problems.

Understanding Torsional Stress

Torsional stress is the stress that arises within a material when it's subjected to a twisting force, or torque. Imagine twisting a metal rod – the internal resistance to this twisting is what we define as torsional stress. This stress is crucial for understanding the behavior of shafts, axles, and other structural components under load.

Unlike tensile and compressive stress which act perpendicularly to a surface, torsional stress acts parallel to the cross-section of the object. Think of it as the shear stress induced by the applied torque.

The Torsional Stress Formula

The formula for calculating torsional stress is fundamental in mechanical engineering and is expressed as:

τ = (T r) / J

Where:

- τ (tau) is the torsional shear stress (typically measured in Pascals (Pa) or pounds per square inch (psi)).

- T is the applied torque (measured in Newton-meters (N·m) or pound-feet (lb·ft)).

- r is the radius from the center of the shaft to the point where the stress is being calculated (measured in meters or inches).

- J is the polar moment of inertia of the cross-section (measured in meters4 or inches4). This represents the object's resistance to torsional deformation.

The polar moment of inertia, J, varies depending on the shape of the cross-section. For a solid circular shaft, J = (π d4) / 32, where d is the diameter. For a hollow circular shaft, J = (π / 32) (D4 - d4), where D is the outer diameter and d is the inner diameter.

Deriving the Torsional Stress Formula

The torsional stress formula is derived from the principles of static equilibrium and the relationship between shear stress and shear strain. It assumes that the material is linearly elastic and obeys Hooke's Law in shear. The derivation involves integrating the shear stress distribution over the cross-sectional area of the shaft and equating it to the applied torque.

Essentially, the formula translates the applied twisting force (torque) into a measure of the internal resistance (stress) within the material, taking into account the geometry of the object.

Applying the Torsional Stress Formula: Solved Problems

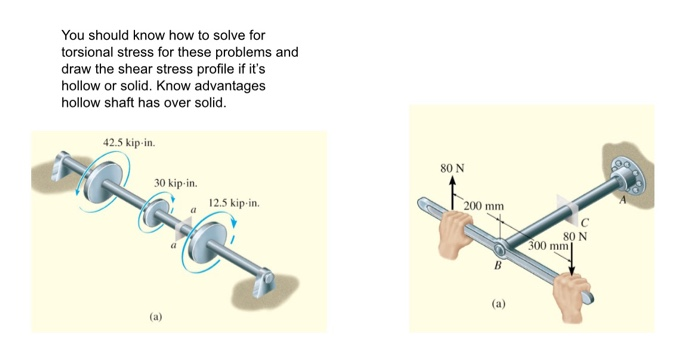

Let’s put the formula into action with some practical examples. These solved problems will help solidify your understanding of how to calculate torsional stress in various scenarios.

Problem 1: Solid Shaft

A solid steel shaft with a diameter of 50 mm is subjected to a torque of 500 N·m. Calculate the maximum torsional shear stress in the shaft.

Solution:

- Calculate the polar moment of inertia (J): J = (π d4) / 32 = (π (0.05 m)4) / 32 ≈

6.136 x 10-8 m4

- Determine the radius (r): r = d / 2 = 0.05 m / 2 =

0.025 m

- Apply the torsional stress formula: τ = (T r) / J = (500 N·m 0.025 m) / (6.136 x 10-8 m4) ≈

20.37 MPa

Therefore, the maximum torsional shear stress in the shaft is approximately 20.37 MPa.

Problem 2: Hollow Shaft

A hollow shaft has an outer diameter of 100 mm and an inner diameter of 60 mm. It is subjected to a torque of 2 k N·m. Determine the torsional shear stress at the outer surface of the shaft.

Solution:

- Calculate the polar moment of inertia (J): J = (π / 32) (D4 - d4) = (π / 32) ((0.1 m)4 - (0.06 m)4) ≈

8.59 x 10-6 m4

- Determine the radius (r): r = D / 2 = 0.1 m / 2 =

0.05 m

- Apply the torsional stress formula: τ = (T r) / J = (2000 N·m 0.05 m) / (8.59 x 10-6 m4) ≈

11.64 MPa

Thus, the torsional shear stress at the outer surface of the hollow shaft is approximately 11.64 MPa.

Problem 3: Material Selection

You are designing a driveshaft that needs to withstand a torque of 1500 N·m. The shaft has a diameter of 40mm. You have two materials to choose from: Aluminum (allowable shear stress = 100 MPa) and Steel (allowable shear stress = 250 MPa). Which material is suitable for this application?

Solution:

- Calculate the required polar moment of inertia (J): J = (π d4) / 32 = (π (0.04 m)4) / 32 ≈

2.51 x 10-7 m4

- Calculate the torsional stress in the shaft: τ = (T r) / J = (1500 N·m 0.02 m) / (2.51 x 10-7 m4) =

119.5 MPa

Comparing this stress to the material properties, 119.5 MPa is greater than the allowable stress for Aluminum (100 MPa) but less than the allowable stress for Steel (250 MPa). Therefore, Steel is the suitable material for this application.

Practical Applications and Considerations

The torsional stress formula is widely used across many engineering disciplines. In automotive engineering, it helps design driveshafts and axles that can handle engine torque without failure. In aerospace, it's used to analyze the stress in rotating components like turbine blades. In civil engineering, it's crucial for designing bridges and structures that resist torsional loads caused by wind or seismic activity.

When applying the torsional stress formula, it's important to remember its limitations. It assumes a linearly elastic material, uniform cross-section, and pure torsion. In real-world scenarios, these assumptions may not always hold true. Factors like stress concentrations (e.g., at sharp corners), material non-linearity, and combined loading conditions can significantly affect the stress distribution.

For complex geometries or loading conditions, Finite Element Analysis (FEA) software is often used to obtain a more accurate stress analysis.

Advantages and Limitations of the Torsional Stress Formula

Advantages:

- Simple and easy to apply for basic geometries.

- Provides a good approximation for initial design and analysis.

- Helps in understanding the fundamental behavior of materials under torsion.

Limitations:

- Assumes linear elasticity, which may not be valid for all materials or loading conditions.

- Does not account for stress concentrations or complex geometries.

- Applicable to uniform cross-sections and pure torsion only.

Torsional Stress vs. Other Types of Stress

It's important to distinguish torsional stress from other types of stress, such as tensile stress, compressive stress, and bending stress. Tensile and compressive stresses act perpendicularly to a surface, while torsional stress acts parallel to the surface. Bending stress, on the other hand, arises from bending moments and creates a combination of tensile and compressive stresses within the material.

Understanding the differences between these types of stress is crucial for conducting accurate stress analysis and designing robust structures.

Key Considerations

When working with torsional stress calculations, remember to pay close attention to units. Ensure consistency in units throughout the calculations (e.g., using meters for length and Pascals for stress). Also, be mindful of stress concentrations, especially in components with sharp corners or abrupt changes in cross-section. These areas are prone to higher stress levels and potential failure.

FAQs About Torsional Stress

What is the difference between torque and torsional stress?

Torque is the twisting force applied to an object, while torsional stress is the internal stress that arises within the object as a result of that torque. Torque is the cause, and torsional stress is the effect.

How does the shape of a shaft affect torsional stress?

The shape of a shaft significantly affects the polar moment of inertia (J), which in turn affects the torsional stress. A shaft with a larger polar moment of inertia will be more resistant to torsion and will experience lower stress levels under the same torque.

What is the factor of safety in torsional stress calculations?

The factor of safety is a design factor that ensures the component can withstand loads greater than the expected service load. It is the ratio of the material's allowable stress to the calculated stress. A higher factor of safety indicates a more conservative design.

What are some real-world examples of torsional stress failures?

Common examples include driveshaft failures in vehicles, wind turbine blade failures, and the failure of axles in rotating machinery. These failures often occur due to exceeding the material's torsional strength or due to fatigue caused by repeated torsional loading.

How can I reduce torsional stress in a design?

You can reduce torsional stress by increasing the polar moment of inertia of the component (e.g., by increasing the diameter or using a hollow shaft), selecting a material with a higher allowable shear stress, or reducing the applied torque.

What are the units for torsional stress?

The standard units for torsional stress are Pascals (Pa) in the metric system or pounds per square inch (psi) in the imperial system.

Conclusion

Understanding the torsional stress formula is a vital skill for anyone involved in mechanical design or analysis. By mastering the formula and its applications, you can confidently design components that can withstand twisting loads, ensuring safety and reliability. Remember to consider the limitations of the formula and use it in conjunction with other analysis tools when necessary. Keep practicing, and you'll be well on your way to tackling even the most complex torsional stress problems.

Posting Komentar untuk "Torsional Stress Formula Explained with Solved Problems"