Maximum Stress Formula in Daily Engineering Practice

Ever wonder how engineers ensure bridges don't collapse or airplane wings don't snap mid-flight? It boils down to understanding stress, and more importantly, knowing themaximumstress a component can withstand. This knowledge, powered by the maximum stress formula, is a cornerstone of structural design and a critical tool in the everyday lives of engineers, impacting everything from the cars we drive to the buildings we live in. So, let's dive in and demystify this vital concept!

Understanding Stress: The Foundation

Stress, in the context of mechanical engineering, is the measure of internal forces acting within a deformable body. These forces arise as a reaction to external forces, like loads or applied forces, that are placed on the object.

Think of it like squeezing a stress ball: the harder you squeeze (the external force), the more internal pressure (stress) builds up within the ball. This pressure is what resists the deformation. Understanding this internal resistance is essential for predicting when a material will yield, break, or otherwise fail.

Types of Stress

Stress isn't a one-size-fits-all concept. It manifests in different forms depending on the nature of the applied force. Two of the most fundamental types are:

Tensile Stress: This occurs when a material is being pulled or stretched. Imagine a rope being tugged – the internal forces resisting that pulling are tensile stress. Compressive Stress: This arises when a material is being squeezed or compressed. A column supporting a roof is a great example, experiencing compressive stress due to the weight above.

Other types include shear stress (like cutting paper with scissors) and bending stress (experienced by a beam under load).

The Maximum Stress Formula: Unveiled

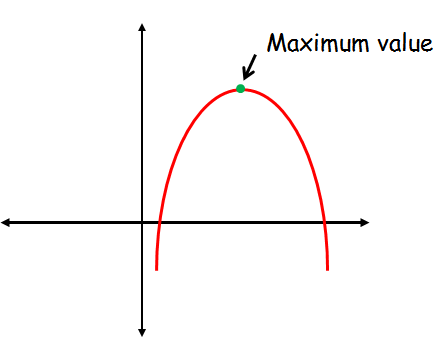

The maximum stress formula isn't a single, universal equation. It varies depending on the loading conditions, the geometry of the object, and the type of stress being analyzed. However, the core principle remains the same: it helps you determine the highest stress value within a component under a specific load.

A Simple Example: Axial Stress

Let's start with a straightforward case: axial stress in a bar subjected to a tensile or compressive force. The formula is:

σ = F/A

Where:

σ (sigma) represents the stress (usually in Pascals or psi)

F is the applied force (in Newtons or pounds)

A is the cross-sectional area of the bar (in square meters or square inches)

This formula gives you the average stress across the cross-section. However, stress concentrations can occur, for example, near holes or sharp corners, leading to amaximumstress significantly higher than the average.

Beyond Axial Stress: More Complex Scenarios

For more complex scenarios, such as bending or torsion, the maximum stress formulas become more intricate. They often involve factors like the bending moment, the section modulus of the object, and the distance from the neutral axis.

For instance, the maximum bending stress (σmax) in a beam is calculated as:

σmax = M y / I

Where:

M is the bending moment

y is the distance from the neutral axis to the outermost fiber

I is the second moment of area (moment of inertia)

These formulas are derived from principles of mechanics of materials and are crucial for accurate structural analysis.

Practical Applications and Case Studies

The maximum stress formula isn't just theoretical; it's a practical tool used in countless engineering applications. Here are a few examples:

Bridge Design: Civil engineers use maximum stress formulas to calculate the stress distribution in bridge beams and supports, ensuring they can withstand the weight of traffic and environmental loads like wind and snow. Aerospace Engineering: Aerospace engineers use complex finite element analysis software and related formulas to determine the maximum stress in airplane wings and fuselage under various flight conditions, ensuring structural integrity and passenger safety. Automotive Engineering:Automotive engineers use stress analysis to optimize the design of car chassis, suspension components, and engine parts to minimize weight and maximize performance without compromising safety.

A famous case study is the de Havilland Comet, the first commercial jet airliner. Early models suffered catastrophic failures due to fatigue cracks initiating at stress concentrations around the square windows. This tragic event highlighted the critical importance of accurate stress analysis and the dangers of overlooking stress concentrations.

Pros and Cons of Using Maximum Stress Formulas

Like any engineering tool, maximum stress formulas have their advantages and limitations:

Pros

Provides a quantitative measure of stress levels.

Allows for predicting material failure under load.

Enables optimization of structural designs.

Contributes to safer and more reliable products and infrastructure.

Cons

Formulas can be complex and require a solid understanding of mechanics of materials.

Assumptions and simplifications inherent in the formulas may not always accurately reflect real-world conditions.

Stress concentrations can be difficult to predict and model accurately.

Material properties (like yield strength) must be accurately known for reliable results.

Step-by-Step Example: Calculating Stress in a Simple Rod

Let's illustrate the use of the axial stress formula with a simple example.

Problem: A steel rod with a diameter of 10 mm is subjected to a tensile force of 5000 N. Calculate the stress in the rod.

Solution:

Calculate the cross-sectional area (A): A = πr2 = π(5 mm)2 =

78.54 mm2 =

78.54 x 10-6 m2

Apply the formula: σ = F/A = 5000 N / (78.54 x 10-6 m2) =

63.66 x 106 N/m2 =

63.66 MPa

Answer: The stress in the steel rod is 63.66 MPa.

FAQs

What is the difference between stress and strain?

Stress is the internal force per unit area within a material, while strain is the deformation of the material caused by that stress. Stress is thecause, and strain is theeffect.

How do stress concentrations affect the maximum stress?

Stress concentrations significantly increase the maximum stress at specific locations, such as corners, holes, or notches. These localized stresses can be several times higher than the average stress in the component, making them critical points for failure analysis.

What is the factor of safety and how is it related to maximum stress?

The factor of safety (FOS) is a design parameter that ensures a structure can withstand loads greater than the expected maximum load. It's calculated as the ratio of the material's strength (e.g., yield strength or ultimate tensile strength) to the maximum stress experienced by the structure under working conditions. A higher FOS indicates a more conservative design.

What is Finite Element Analysis (FEA) and how does it help in stress analysis?

FEA is a numerical technique used to approximate the solution of complex engineering problems, including stress analysis. It divides a structure into small elements and solves equations to determine the stress and strain distribution throughout the object. FEA is particularly useful for analyzing complex geometries and loading conditions where analytical solutions are not feasible.

How do temperature changes affect maximum stress?

Temperature changes can induce thermal stresses in materials due to thermal expansion or contraction. If a material is constrained, these thermal stresses can be significant and must be considered in addition to stresses caused by external loads. Thermal stress can be calculated using material properties such as coefficient of thermal expansion and Young's modulus.

What are some common software tools used for stress analysis?

Popular software tools for stress analysis include ANSYS, Abaqus, Solid Works Simulation, and COMSOL Multiphysics. These programs use FEA to simulate stress distributions in various structures and components under different loading scenarios.

Conclusion

Mastering the maximum stress formula, understanding its applications, and recognizing its limitations are essential skills for any engineer involved in structural design and failure analysis. While formulas provide a foundation, always remember the importance of considering real-world factors, material properties, and potential stress concentrations. By continuously learning and applying these principles, you can contribute to creating safer, more efficient, and more reliable engineered systems. Keep exploring, keep calculating, and keep building!

Posting Komentar untuk "Maximum Stress Formula in Daily Engineering Practice"