Centrifugal Stress Formula in Rotating Discs and Rings

Ever wondered how the incredible speeds of a jet engine turbine are possible without the whole thing flying apart? The secret lies, in part, with understanding and managing centrifugal stress. This stress, generated by the rotational forces on components like discs and rings, is crucial for designing safe and efficient rotating machinery. For engineers, students of mechanical engineering, and professionals in the field, mastering the centrifugal stress formula is essential for structural design and ensuring material strength against failure.

Understanding Centrifugal Stress

Centrifugal stress arises from the inertia of a rotating object's mass. Imagine a point on a spinning disc; it wants to continue moving in a straight line, but is constrained by the material around it, resulting in outward forces. These forces translate into tensile stress within the disc, pulling it apart.

The magnitude of this stress is influenced by several factors: the rotational speed (measured in radians per second), the density of the material, and the geometry of the rotating component.

Derivation of the Centrifugal Stress Formula

Let’s break down the centrifugal stress formula. For a thin rotating ring, the tensile stress (σ) can be approximated by:

σ = ρ v²

Where:

- σ = Tensile stress (Pascals or psi)

- ρ = Density of the material (kg/m³ or lb/in³)

- v = Linear velocity at the mean radius (m/s or in/s)

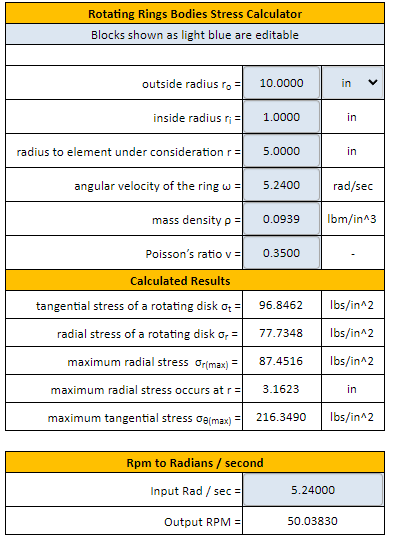

This formula gives a simplified view. A more complex version, applicable to rotating discs with a hole at the center, considers the radius (r), angular velocity (ω), and Poisson's ratio (ν) of the material:

σ_t = (3 + ν)/8 ρ ω² (R² + r²)

σ_r = (3 + ν)/8 ρ ω² (R² - r²)

Where:

- σ_t = Tangential stress (hoop stress)

- σ_r = Radial stress

- ω = Angular velocity (rad/s)

- R = Outer radius

- r = Inner radius (if applicable)

- ν = Poisson's ratio

Factors Affecting Centrifugal Stress

Several factors significantly influence centrifugal stress, including rotational speed. Higher speeds lead to greater stress. Material density also plays a crucial role; denser materials experience higher stress levels. The geometry of the rotating component – its shape, dimensions, and any holes or discontinuities – will concentrate stress in specific areas, making proper design crucial.

Calculating Centrifugal Stress: A Step-by-Step Example

Let's calculate the tangential stress in a rotating steel disc. Assume the following:

- Density (ρ) = 7850 kg/m³

- Outer Radius (R) = 0.2 m

- Inner Radius (r) = 0.05 m

- Angular Velocity (ω) = 500 rad/s

- Poisson's Ratio (ν) = 0.3

Step 1: Apply the formula:

σ_t = (3 + ν)/8 ρ ω² (R² + r²)

Step 2: Substitute the values:

σ_t = (3 + 0.3)/8 7850 kg/m³ (500 rad/s)² ((0.2 m)² + (0.05 m)²)

Step 3: Calculate the result:

σ_t ≈ 20.2 MPa

Therefore, the tangential stress in the rotating steel disc is approximately 20.2 MPa.

Practical Applications and Case Studies

Understanding centrifugal stress is crucial in various engineering applications. In turbine design, accurately predicting and mitigating this stress is vital for safe and efficient power generation. The design of flywheels for energy storage also depends heavily on understanding centrifugal forces. Automotive components such as brake rotors and clutch discs must be designed to withstand these stresses, too.

Consider a case study of a turbine failure due to exceeding the material's tensile strength under centrifugal load. Failure analysis often reveals design flaws or material defects that contributed to the premature failure. Such incidents highlight the importance of accurate stress calculations and robust material selection.

Pros and Cons of Different Materials

The choice of material for rotating discs and rings is critical in managing centrifugal stress. Steel alloys are commonly used due to their high tensile strength and relatively low cost. However, they can be heavy. Titanium alloys offer excellent strength-to-weight ratios, making them suitable for high-speed applications but are more expensive. Composite materials, while lightweight, might require careful design considerations to address anisotropic properties.

Each material presents a trade-off between strength, density, cost, and manufacturing feasibility. A thorough understanding of material properties is essential in structural design.

Mitigation Strategies for Centrifugal Stress

Several strategies can be employed to mitigate the effects of centrifugal stress. One approach is to use materials with higher tensile strength. Another is to optimize the geometry of the rotating component to minimize stress concentrations. Interference fits, where one component is slightly larger than the hole it fits into, can pre-compress the material, counteracting tensile stresses.

Advanced manufacturing techniques, such as autofrettage (pre-stressing) and the use of fiber-reinforced composites, also offer effective solutions for managing centrifugal stress.

Frequently Asked Questions

What happens if centrifugal stress exceeds the material's tensile strength?

If the centrifugal stress surpasses the material's tensile strength, the component will likely experience plastic deformation or fracture, leading to failure. This is why accurate stress analysis and material selection are crucial during the design phase.

How does temperature affect centrifugal stress?

Temperature can significantly affect material properties, including tensile strength and elasticity. Elevated temperatures generally reduce tensile strength, making the component more susceptible to failure under centrifugal stress. Thermal expansion can also induce additional stresses.

What is the role of finite element analysis (FEA) in centrifugal stress analysis?

FEA is a powerful tool for simulating and analyzing complex stress distributions in rotating components. It allows engineers to identify stress concentrations and optimize designs to minimize the risk of failure. FEA can handle complex geometries and material properties that are difficult to analyze analytically.

Can centrifugal stress be beneficial?

In some cases, yes. Pre-stressing techniques, like autofrettage, intentionally induce compressive stresses to counteract tensile centrifugal stresses during operation, enhancing the component's overall strength and fatigue life. This is particularly useful in high-pressure applications.

What is the difference between radial and tangential stress in a rotating disc?

Radial stress acts along the radius of the disc, while tangential stress (also known as hoop stress) acts circumferentially. Both stresses are generated by centrifugal forces, but their directions and magnitudes vary depending on the location within the disc. Typically, tangential stress is higher at the inner radius of a rotating disc with a hole.

How does the presence of a hole affect centrifugal stress in a disc?

The presence of a hole introduces a stress concentration, particularly around the hole's edge. This means the stress levels near the hole will be significantly higher than in other parts of the disc, increasing the risk of failure initiation at that location.

Conclusion

Mastering the centrifugal stress formula and understanding its implications are fundamental for engineers and designers working with rotating machinery. By accurately calculating and mitigating this stress, we can create safer, more efficient, and more reliable systems. Remember to consider material properties, geometry, and operating conditions to ensure the integrity and longevity of your designs. Your ability to apply these principles effectively will be a key driver of innovation and progress in mechanical engineering and beyond.

Posting Komentar untuk "Centrifugal Stress Formula in Rotating Discs and Rings"